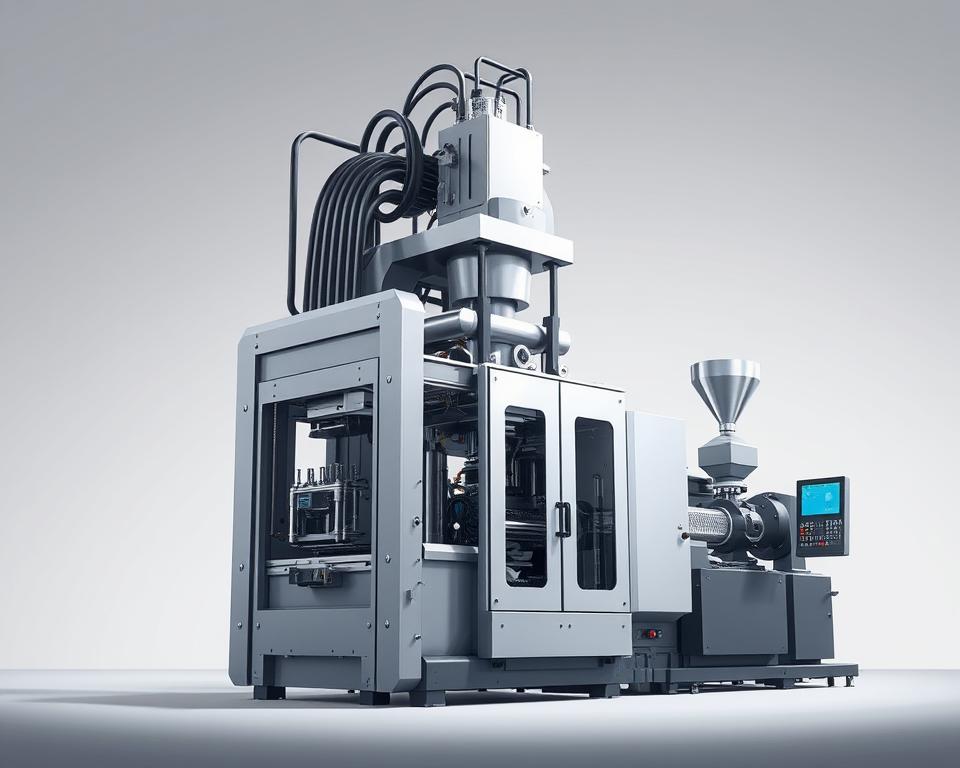

How to Source Injection Molding Services from China

The important meeting has recently finished, your new product has been approved, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. The cost savings can be huge. But your mind is already racing. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

However, here’s the reality. Procuring China injection molding needn’t be a roll of the dice. It’s no different from any structured project. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This becomes the bedrock of your sourcing project.

So, what goes in it?

Start with your 3D design files. They’re essential. Use standard formats such as STEP or IGS to ensure compatibility. This serves as the definitive part geometry reference.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. Here you specify what 3D can’t show. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

After that, material choice. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Get precise. Call out SABIC Cycolac MG38 (black), for example. What’s the reason? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. What is your Estimated Annual Usage (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

Now that your RFQ is pristine. who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Finding suppliers is simple; finding quality ones is tough.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They let you survey dozens of suppliers quickly. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

Still, you must dig deeper. Perhaps hire a local sourcing specialist. They do cost extra. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Another tactic: trade exhibitions. With budget permitting, Chinaplas or similar shows are invaluable. Meeting onsite is unbeatable. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It blends technical checks with intuition.

Begin with responsiveness. Is their turnaround swift and concise? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? The best firms will question and suggest. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Next up: the factory audit. Skipping this is a mistake. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s a tiny cost for huge peace of mind.

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. It’s your first real test.

Expect T1s to need tweaks. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. This process might take a couple of rounds. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Finally, a flawless part arrives. Dimensions, finish, and performance all check out. This is now the benchmark sample. You sign off, and it serves as the master quality reference.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

Implement a robust QC plan. This often involves a pre-shipment inspection. Again, you can hire a third-party service. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Finally, think about logistics. Understand the shipping terms, or Incoterms. Does FOB apply, passing risk at the ship’s rail? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These choices hugely affect landed cost.

Sourcing from China is a marathon, not a sprint. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.